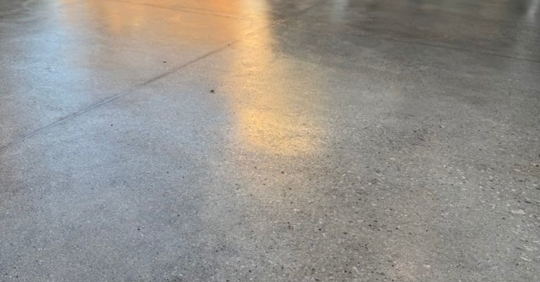

Visual Cues: Spotting Changes in Appearance

Concrete floors can exhibit several visual cues that suggest the need for polishing. Over time, your once-shiny floors may start to show discoloration, lose their gloss, and develop visible wear patterns. These changes in appearance often result from foot traffic, exposure to sunlight, or even chemical spills. As your floor ages, it might lose its uniform color, which is an indication that the surface is wearing down and needs attention. Stains from spills and liquid penetration further mar the floor’s aesthetic, creating an uneven and dull look. Etches, which are slight depressions caused by harsh substances, can disrupt the smoothness of your floor, giving it an undesirable texture that signals it's time for rejuvenation through polishing.

Tactile Indicators: Feeling the Surface

Beyond visual signs, the tactile experience of your concrete floor can also indicate the need for polishing. A well-polished floor feels smooth and even underfoot, offering a sense of stability and comfort. However, when a floor turns rough or uneven, it not only affects the aesthetic appeal but also suggests surface degradation. Walking barefoot or sliding your hand across a dull concrete surface reveals an abrasive texture compared to the silky touch of a polished one. This sensation is due to micro-abrasions and scratches that accumulate over time, eroding the floor’s protective layer. Such tactile indicators should act as a cue to schedule polishing, ensuring your floor regains its inviting feel and smooth texture.

Regular Maintenance Schedules: Establishing a Routine

To preserve the beauty and functionality of your concrete floors, establishing a regular maintenance schedule is crucial. Homeowners and facility managers should frequently assess their floors to identify signs of wear before they become significant problems. In residential settings, a thorough inspection every six months is generally sufficient to catch early warning signs. On the other hand, commercial spaces, which endure higher foot traffic, may benefit from quarterly inspections. Regular assessments help in planning timely interventions, like a restorative polish, which can ward off costly repairs and maintain a polished floor's gloss and durability over the years.

DIY Inspection: Tools and Techniques

Conducting a DIY inspection can be both cost-effective and informative. It equips you with the ability to monitor your floor’s condition between professional assessments. Essential tools for such inspections include moisture meters, which detect levels of moisture that might damage the floor, and gloss meters, which measure the surface’s shine. Start by scanning your floor for surface inconsistencies and decolorations. Follow this by checking the floor's smoothness with your hands or a cloth. Finally, use the gloss meter to compare shine levels across different areas. This hands-on approach not only aids in maintaining your floors but also deepens your understanding of their needs and performance.

Enhanced Aesthetic Appeal: Boosting Visual Impact

Polished concrete floors are celebrated for their aesthetic appeal, instantly elevating the look of any space. The polishing process enhances the natural colors of concrete, increasing its reflectivity and transforming an uninspiring floor into a striking centerpiece. This enhancement makes spaces appear larger and more inviting, a reason they are favored both in residential living areas and commercial properties. Furthermore, decorative elements such as dyes, stains, and artistic scoring can be incorporated during polishing, offering endless possibilities to customize your flooring to match your style or brand, making polished concrete a versatile choice for boosting visual impact.

Functional Advantages: Efficiency and Maintenance

Beyond its beauty, polished concrete provides numerous functional benefits. One major advantage is increased durability; polished floors withstand heavy traffic and resist stains far better than untreated concrete. This attribute makes them ideal for both homes and business establishments, where maintenance is simplified to routine cleaning with water and mild detergents. Polished concrete also plays a role in enhancing light reflectivity within a space, reducing the need for additional lighting and ultimately lowering energy costs. These practical benefits not only contribute to easier maintenance but also promote a more sustainable and cost-effective flooring solution.

Selecting the Right Polish: Factors to Consider

Choosing the correct polish for your concrete floors requires consideration of several factors, including traffic levels and environmental impact. High-traffic areas, like hallways and commercial entrances, demand a more resilient polish that can withstand wear and tear. Additionally, eco-friendly polishes, which are low in volatile organic compounds (VOCs), are excellent for those conscious about their environmental footprint and indoor air quality. These products not only provide excellent surface protection but also support global sustainability efforts. Selecting the right polish involves balancing performance, aesthetics, and ecological considerations to achieve the best possible outcome for your flooring needs.

Professional vs. DIY Polishing: Making the Choice

When it comes to polishing your concrete floors, deciding between a professional service and a DIY approach can significantly affect the final results. Professional services offer expertise and advanced equipment that can efficiently tackle complex projects, ensuring a high-quality finish. They are recommended for larger spaces or severely worn floors that require intricate repair work. However, for minor touch-ups, a DIY effort, guided by proper research and tools, can be rewarding and cost-effective. Consider factors like time, budget, and desired finish quality. If uncertain or if the floor’s condition appears critical, hiring professionals can deliver long-lasting, impeccable results.

Environmental Factors: Adapting to Conditions

Environmental conditions play a critical role in the maintenance of polished concrete floors. Variations in temperature and humidity can impact the floor's integrity and appearance. In areas with high humidity, additional measures such as dehumidifiers might be necessary to prevent moisture-related issues. Cold weather can make the floor more susceptible to cracking, necessitating adjustments in maintenance practices. For indoor conditions, regular dusting and using entry mats can reduce the amount of grime and maintain the floor's shine. Being mindful of these factors and adapting maintenance routines accordingly ensures the longevity and resiliency of your polished floors.

Advanced Care Techniques: Extending Floor Lifespan

To maximize the lifespan of polished concrete floors, advanced care techniques should be integrated into routine maintenance. Periodic sealing offers an additional layer of protection against stains and moisture, helping preserve the floor’s sheen. Re-polishing, done every few years, refreshes the floor's appearance and can correct minor blemishes that accumulate over time. Moreover, implementing protective measures—such as felt padding under furniture and area rugs in high-traffic zones—reduces the risk of abrasion and wear. Proactively managing foot traffic by rerouting paths or setting up designated walkways also plays a crucial role in maintaining the polished surface's pristine condition.

Make the Smart Choice for Your Concrete Floors with Luxe Pro Finish Concrete Floor Coatings

Investing in polished concrete floors promises both aesthetic enhancement and functional advantages. If your home or business is looking to restore the brilliance of its concrete surfaces, Luxe Pro Finish Concrete Floor Coatings offers expert services tailored to your specific flooring needs. Our experienced professionals ensure high-quality polishing that can transform and prolong the life of your floors. Contact us today to explore your options and schedule a consultation. Don’t settle for dull and worn; let us bring your floors back to life.

Call Luxe Pro Finish Concrete Floor Coatings now at (248) 213-8680 or send us a message online.